Example 4 - Stepping Analysis of a Synchronous Machine

Goal: Perform magnetostatic stepping over different rotor angles, for a synchronous machine.

Result: Different waveform plots, flux density plots, and a structure of important performance indicators.

Prequisites

Making sure that a model has already been initialized.

if ~exist('motor', 'var')

Example_01_Setting_up_a_Model;

close all;

end

gmsh path E:\Software\Work\gmsh-4.11.1\ loaded from preference group 'emdtool'

Name Size Bytes Class Attributes

motor 1x1 8 RFmodel

Background

This example analyses a synchronous (PM) machine at a single operating point (constant rpm, sinusoidal phase currents), using what is called ‘static analysis’ in EMDtool. Here, ‘static’ refers to the fact that that eddy currents and similar damping effects are ignored, otherwise it works very much like what one would expect from a constant-rpm transient simulation with imposed current waveforms.

Initializations

We again begin by instantiating a MagneticsProblem object

problem = MagneticsProblem.new(motor);

and then specify the operating point to analyse

rpm = 3000; %rpm

Jrms = 10e6; %rms current density

pole_angle = pi/180 * 90; %Note: 90 degrees corresponds to id = 0

Finally, to keep things fast, we only analyse one sixth of the electrical period (enough for typical distributed-wound machines in ideal steady-state) using a moderate 11 steps

angles = linspace(0, 2*pi/6, 11); %electrical angles to step through

Running the analysis

Setting the excitation

First, we compute the current waveforms corresponding to our desired rms current, pole angle, and number of steps:

phase_circuit = stator.winding;

spec = stator.winding_spec;

Ipeak = sqrt(2)*Jrms * phase_circuit.conductor_area_per_turn_and_coil();

Is = spec.xy(Ipeak*[cos(pole_angle); sin(pole_angle)], angles);

Next, we set the just-computed waveforms as the excitation for the stator winding, exactly in the same fashion as we did in the torque curve example:

phase_circuit.set_source('uniform coil current', Is);

Simulation parameters

Next, we define the simulation parameters. For static stepping, the only crucial parameters are typically the frequency and the (mechanical) rotor angles to step through:

%parameters

pars = SimulationParameters('f', rpm/60*dim.p, 'rotorAngle', angles/dim.p, ...

'silent', ~true);

Solution

Next, the problem is solved.

stepping_solution = problem.solve_static(pars);

Computing step/case 1 out of 11...

Newton step 1, relative residual 1.

Newton step 2, relative residual 18.043.

Relaxation automatically set to 0.9

Newton step 3, relative residual 3.3023.

Newton step 4, relative residual 1.2495.

Newton step 5, relative residual 0.19708.

Newton step 6, relative residual 0.059244.

Newton step 7, relative residual 0.021485.

Newton step 8, relative residual 0.0069899.

Newton step 9, relative residual 0.0021695.

Newton step 10, relative residual 0.00094776.

Newton step 11, relative residual 0.00049132.

Newton step 12, relative residual 0.00020549.

Newton step 13, relative residual 7.0589e-05.

Newton step 14, relative residual 2.1045e-05.

Newton step 15, relative residual 7.1874e-06.

Newton step 16, relative residual 1.6706e-07.

Computing step/case 2 out of 11...

Newton step 1, relative residual 9.1616.

Newton step 2, relative residual 0.029239.

Newton step 3, relative residual 0.0017543.

Newton step 4, relative residual 7.7909e-05.

Newton step 5, relative residual 3.532e-06.

Newton step 6, relative residual 2.6741e-08.

Computing step/case 3 out of 11...

Newton step 1, relative residual 9.0937.

Newton step 2, relative residual 0.014582.

Newton step 3, relative residual 0.00062131.

Newton step 4, relative residual 5.0827e-05.

Newton step 5, relative residual 3.7208e-06.

Newton step 6, relative residual 8.4766e-08.

Computing step/case 4 out of 11...

Newton step 1, relative residual 9.0544.

Newton step 2, relative residual 0.012704.

Newton step 3, relative residual 0.0014285.

Newton step 4, relative residual 7.5252e-05.

Newton step 5, relative residual 1.4031e-06.

Newton step 6, relative residual 3.8154e-08.

Computing step/case 5 out of 11...

Newton step 1, relative residual 9.0768.

Newton step 2, relative residual 0.0071109.

Newton step 3, relative residual 0.00034649.

Newton step 4, relative residual 1.8286e-05.

Newton step 5, relative residual 4.0907e-07.

Computing step/case 6 out of 11...

Newton step 1, relative residual 9.1055.

Newton step 2, relative residual 0.01162.

Newton step 3, relative residual 0.0018736.

Newton step 4, relative residual 0.00023072.

Newton step 5, relative residual 7.4157e-06.

Newton step 6, relative residual 1.962e-07.

Computing step/case 7 out of 11...

Newton step 1, relative residual 9.0779.

Newton step 2, relative residual 0.053552.

Newton step 3, relative residual 0.0052944.

Newton step 4, relative residual 0.00033058.

Newton step 5, relative residual 1.2514e-05.

Newton step 6, relative residual 2.355e-07.

Computing step/case 8 out of 11...

Newton step 1, relative residual 9.0271.

Newton step 2, relative residual 0.020056.

Newton step 3, relative residual 0.00066775.

Newton step 4, relative residual 8.8412e-05.

Newton step 5, relative residual 1.2657e-05.

Newton step 6, relative residual 8.6345e-07.

Computing step/case 9 out of 11...

Newton step 1, relative residual 9.0173.

Newton step 2, relative residual 0.08393.

Newton step 3, relative residual 0.012441.

Newton step 4, relative residual 0.0039697.

Newton step 5, relative residual 0.0010366.

Newton step 6, relative residual 6.9793e-05.

Newton step 7, relative residual 1.2795e-06.

Newton step 8, relative residual 1.4703e-08.

Computing step/case 10 out of 11...

Newton step 1, relative residual 9.0903.

Newton step 2, relative residual 0.010136.

Newton step 3, relative residual 0.0011861.

Newton step 4, relative residual 0.00011047.

Newton step 5, relative residual 1.5789e-05.

Newton step 6, relative residual 8.9525e-07.

Computing step/case 11 out of 11...

Newton step 1, relative residual 9.1738.

Newton step 2, relative residual 0.010179.

Newton step 3, relative residual 0.0014181.

Newton step 4, relative residual 0.00020407.

Newton step 5, relative residual 2.412e-05.

Newton step 6, relative residual 9.4879e-07.

Post-processing

Plotting

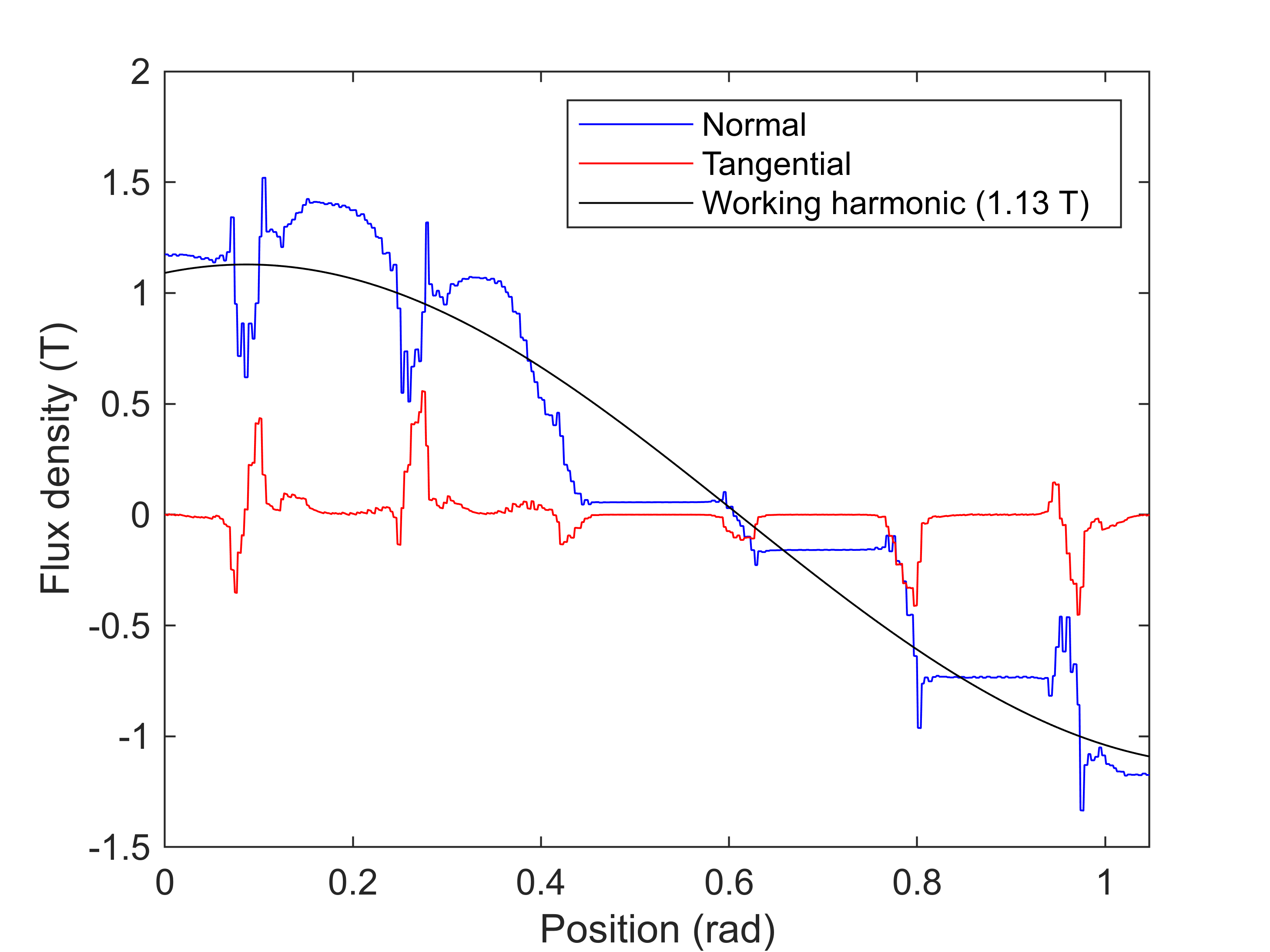

We proceed to plot the airgap flux density waveform,

figure(4); clf; hold on; box on;

motor.plot_airgap_flux_density(stepping_solution, 11)

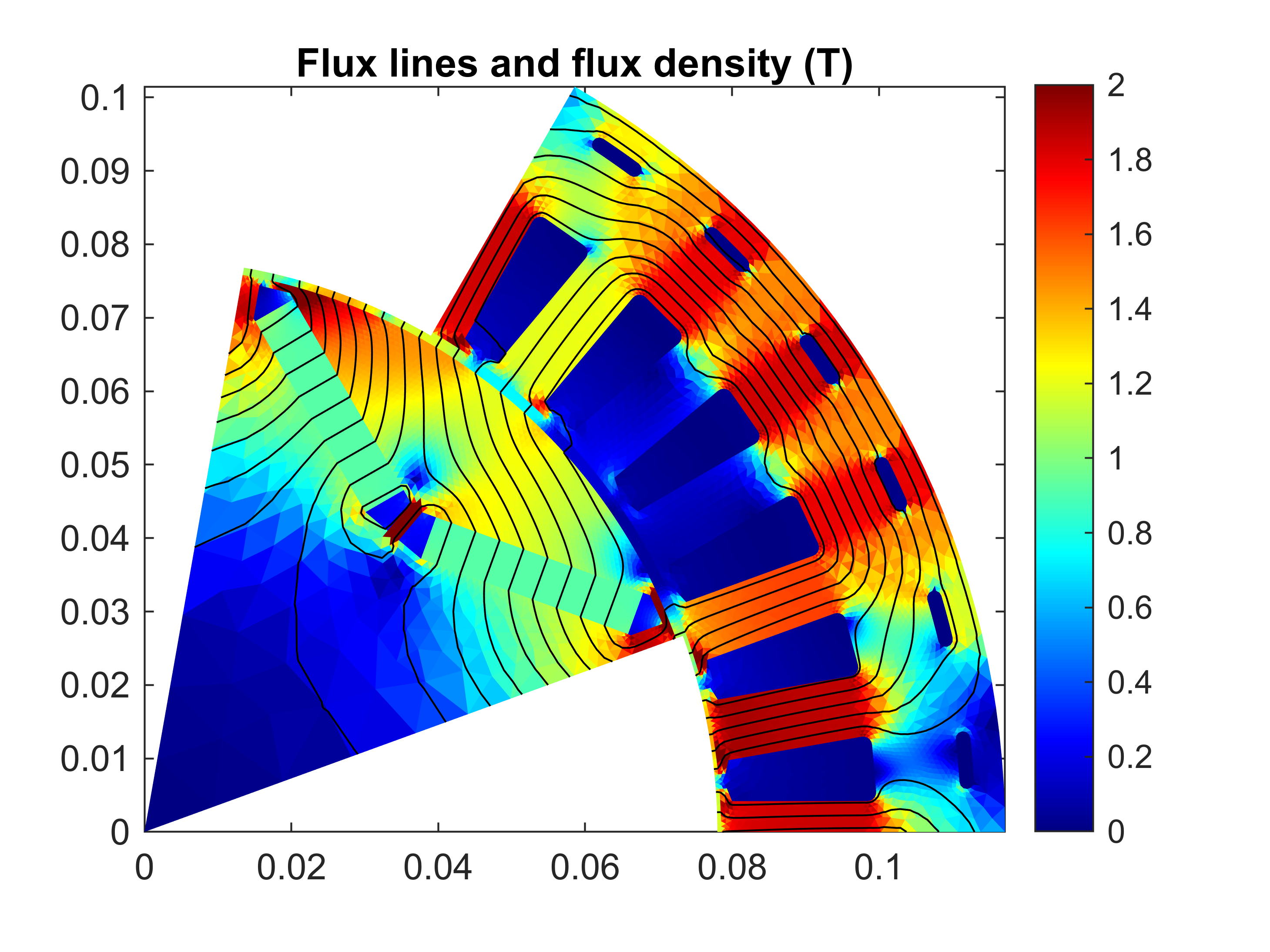

the flux density distribution at step 11,

%plotting example of flux

figure(5); clf; hold on; box on;

motor.plot_flux(stepping_solution, 11);

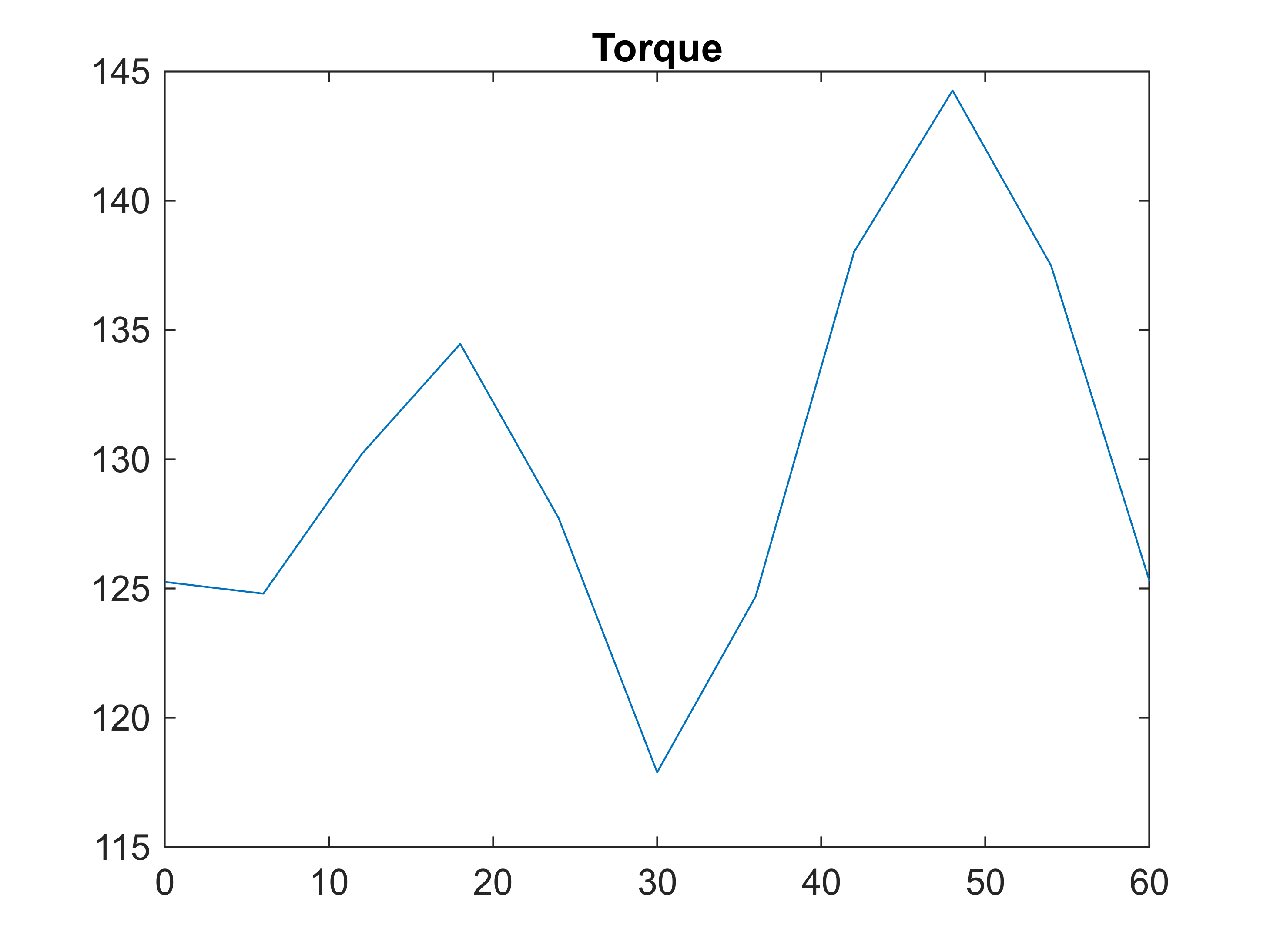

the torque waveform

%plotting torque

T = motor.compute_torque( stepping_solution );

figure(6); clf; hold on; box on; title('Torque');

plot(angles/pi*180, T);

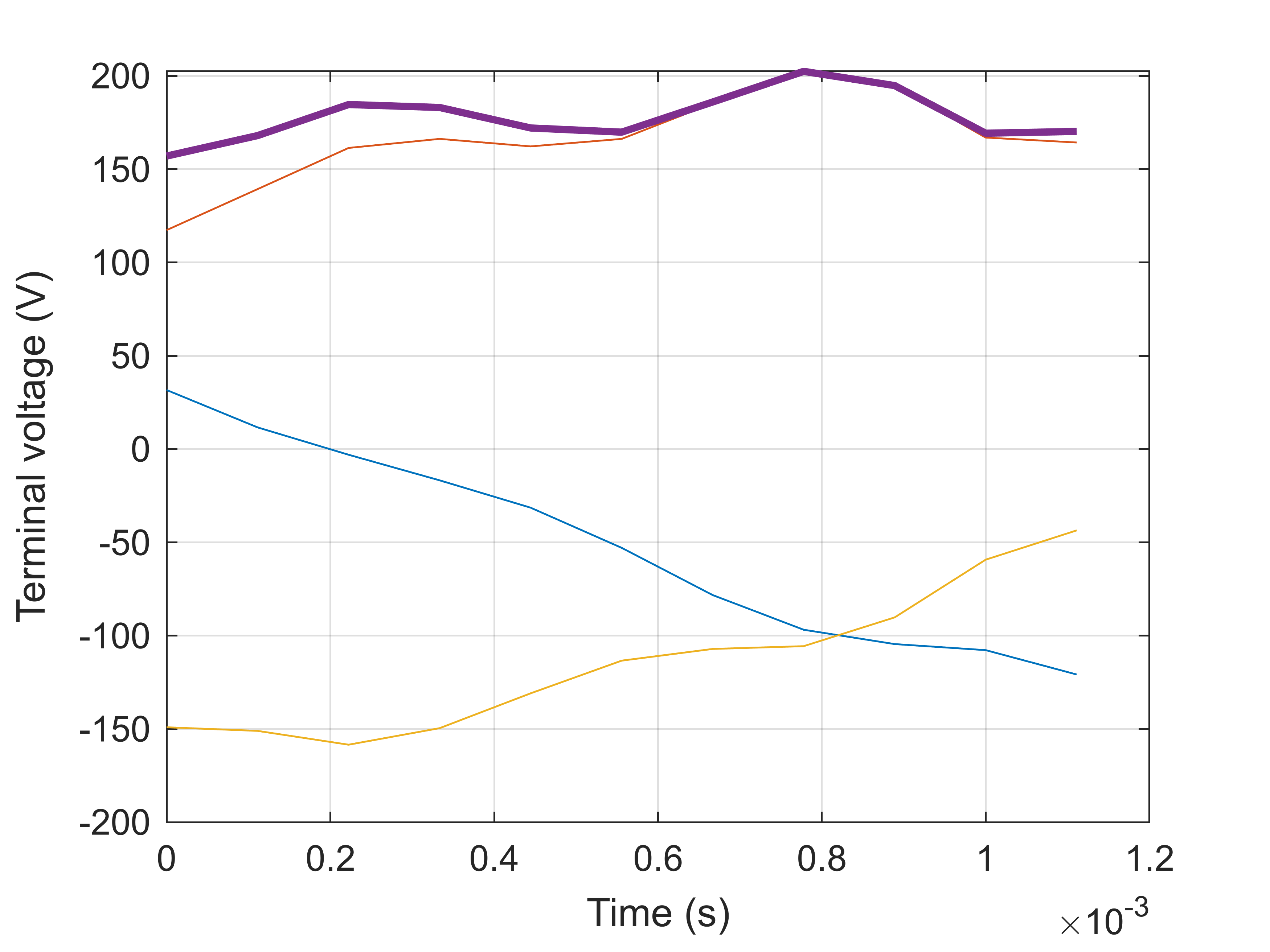

and some voltage waveforms (note that the ‘back-emf’ method returns the simply the time-derivative of the flux linkage, without differentiating whether it’s inductive or PM/field-winding related)

%voltages

voltage = phase_circuit.terminal_voltage(stepping_solution);

voltage_dq = phase_circuit.terminal_voltage( stepping_solution, 'output', 'space vector');

phase_voltage = phase_circuit.phase_bemf(stepping_solution);

phase_voltage_dq = phase_circuit.phase_voltage(stepping_solution, 'output', 'space vector');

%plotting

figure(7); clf; hold on; box on; grid on;

plot(stepping_solution.ts, voltage);

plot(stepping_solution.ts, colnorm(voltage_dq), 'linewidth', 2);

xlabel('Time (s)');

ylabel('Terminal voltage (V)');

Results summary

Finally and importantly, we compute the results summary with the MotorModelBase.results_summary method. The method returns a Matlab structure; in addition we are giving the 'verbose' argument to also display the results in the Matlab command window.

summary = motor.results_summary(stepping_solution, 'verbose', true);

Warning: The extruded block height 150 mm is less than the skin depth (17.608 mm) at 10x fundamental frequency. The results may be inaccurate. Consider running a transient simulation / setting the circuit as active.

Summary of results:

git_commit_ID : 8cced832b0ccd486ccf7bbeb18d29643f015c25c

rpm : 3000

f : 150

torque_waveform : (array)

torque_mean : 130.0088

shaft_power : 40843.4653

torque_ripple_min_to_max : 26.3679

torque_ripple_rms : 7.5695

timestamps : (array)

efficiency : 0.95693

total_losses : 1838.3056

input_power_from_power_balance : 42681.7709

input_power_from_terminal_waveforms : 42348.0453

**********************************************************

phase_circuit_data:

input_power : 42348.0453

input_power_waveform : (array)

apparent_input_power : 52594.4956

displacement_power_factor : 0.6792

I_phase_waveform : (array)

I_phase_dq : 8.141787e-14 404.7173

I_phase_rms : 286.1783

phase_advance_angle_deg : -1.4211e-14

I_terminal_waveform : (array)

I_terminal_rms : 286.1783

I_terminal_THD : 2.0206e-31 2.8878e-32 3.4654e-32

U_phase_waveform : (array)

U_phase_induced : (array)

U_phase_dq : -75.3802 69.7574

U_phase_rms : 73.4122

U1_phase_rms : 72.6233

phase_flux_linkage : (array)

U_terminal_waveform : (array)

U_terminal_rms : 127.1536

U1_terminal_rms : 125.7872

coil_current_density_rms : 10000000

supply_mode : uniform coil current

**********************************************************

total_iron_losses : 437.8727

**********************************************************

iron_loss_data:

P_total : 437.8727

P_total_time : (array)

P_hysteresis : 337.8309

P_rotor : 35.7423

P_hysteresis_rotor : 30.859

P_eddy_rotor : 4.8834

P_eddy : 100.0418

P_excess : 0

P_excess_rotor : 0

p_hysteresis_elementwise : (array)

p_eddy_elementwise : (array)

p_excess_elementwise : (array)

**********************************************************

iron_losses_per_domain:

stator_Stator_core : 402.1304

stator_Stator_slot_opening : 0

stator_Stator_winding_segment : 0

stator_Cooling_channel : 0

rotor_Core : 35.6747

rotor_Shaft : 0.067674

rotor_Air : 0

rotor_Magnet_1 : 0

rotor_Magnet_2 : 0

**********************************************************

**********************************************************

total_circuit_losses : 1400.4329

total_Phasewinding_losses : 1395.3803

**********************************************************

Phasewinding_loss_data:

conductor_loss_waveform : (array)

mean_total_losses : 1395.3803

mean_AC_losses : 0

mean_DC_losses : 1395.3803

mean_EW_losses : 653.0731

mean_conductor_losses : 40.93833 40.93833 310.9356 310.9356 345.8162 345.8162

mean_circulating_current_losses : 2.2737e-13

mean_circulating_current_losses_on_phase_level : 0

total_DC_losses : (array)

**********************************************************

total_Magnets_losses : 3.5317

**********************************************************

Magnets_loss_data:

mean_losses_per_conductor : 1.6725 1.8592

conductor_loss_waveform : (array)

**********************************************************

total_Shaft_losses : 1.5208

**********************************************************

Shaft_loss_data:

mean_losses_per_conductor : 1.5208

conductor_loss_waveform : (array)

elementwise_current_density_array : (array)

**********************************************************

NEXT UP: Example 05 Transient Analysis of Synchronous Machine