Example 7 - Demagnetization Analysis of a Synchronous Machine

Goal: Evaluate demagnetization behaviour using an advanced nonlinear demagnetization model.

Result: Amount of torque lost with the same current supply, plus visualizations of the magnet damage.

Prequisites

Making sure that a model has already been initialized.

if ~exist('motor', 'var')

Example_01_Setting_up_a_Model;

close all;

end

gmsh path E:\Software\Work\gmsh-4.11.1\ loaded from preference group 'emdtool'

Name Size Bytes Class Attributes

motor 1x1 8 RFmodel

Using an Advanced Material Model

Next, we change the permanent magnet material from the default Material class with its linear magnetization behaviour, to a step more advanced model called the DemagMaterial1.

First, we initialize the material from the already-set linear material, copying all the basic properties.

demag_material = DemagMaterial1().from_material(dim.magnet_material);

Next, we specify the behaviour we want. First, we set the material to use a single analytical exponential-style demagnetization model. While we could explicitly specify a demagnetization curve to use, this is way faster.

demag_material.use_simple_model = true;

Next, in order to model the effect of a short-circuit scenario on the motors subsequent behaviour, we instruct the material to remember any permanent demagnetization it has encountered.

demag_material.retain_state = true;

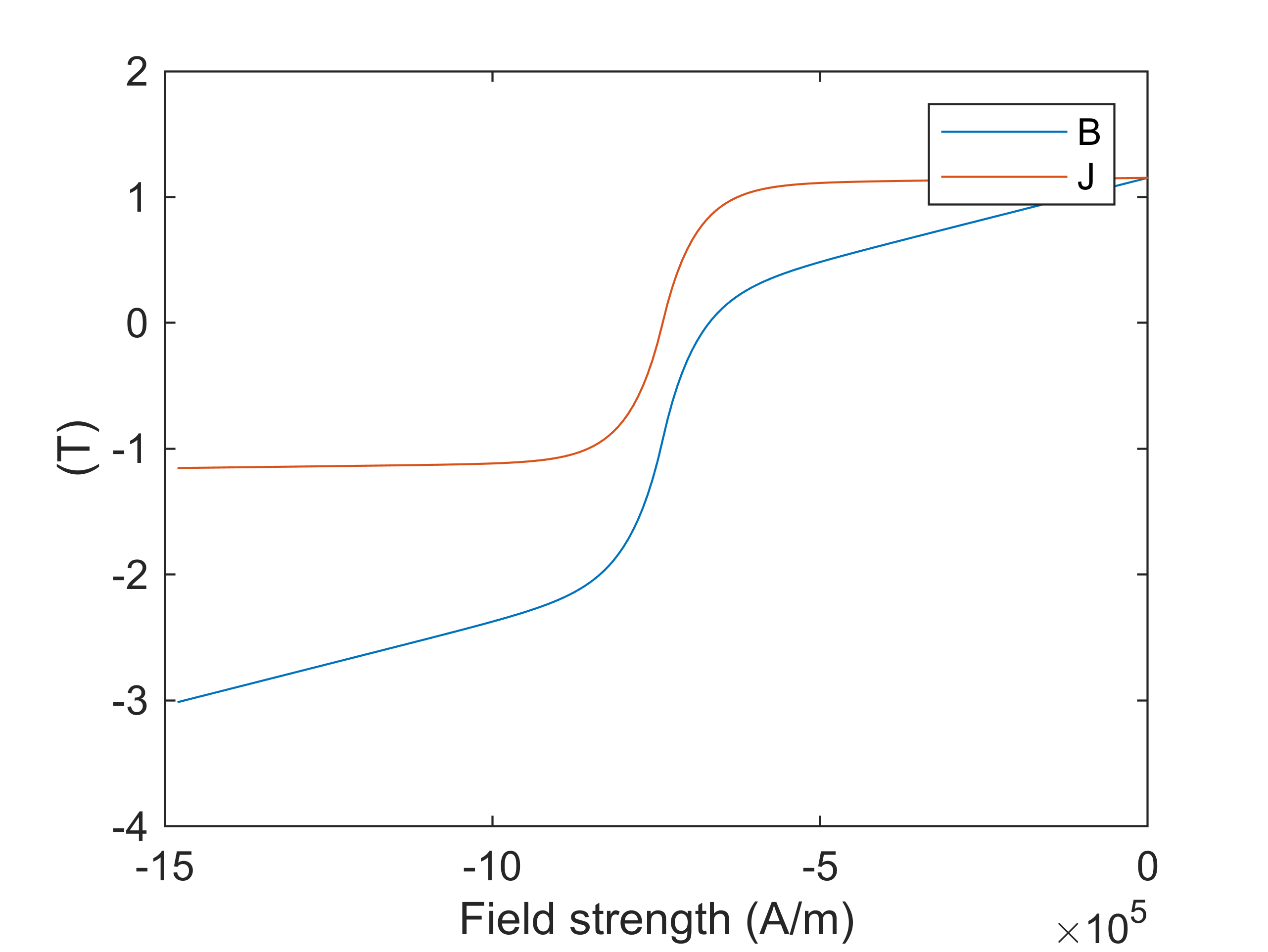

Finally, we visualize the modelled BH and BJ curves. For this, we need to first initialize the simple model for the given rotor remperature. Please note that when initializing a MagneticsProblem object, the model is re-initialized for the rotor temperature seen by the problem at that time.

demag_material.initialize_simple_model(dim.temperature_rotor);

figure(3); clf; hold on; box on;

demag_material.visualize_demag_curve();

Finally, we re-initialize our motor model to use the new material model.

dim.magnet_material = demag_material;

stator = Stator(dim);

rotor = VIPM1(dim);

motor = RFmodel(dim, stator, rotor);

Finally, since the geometry templates normally create their own copies of the materials given, we fetch and re-assign our demag_material variable to point to the object actually used by the model

demag_material = rotor.materials.get(demag_material.name);

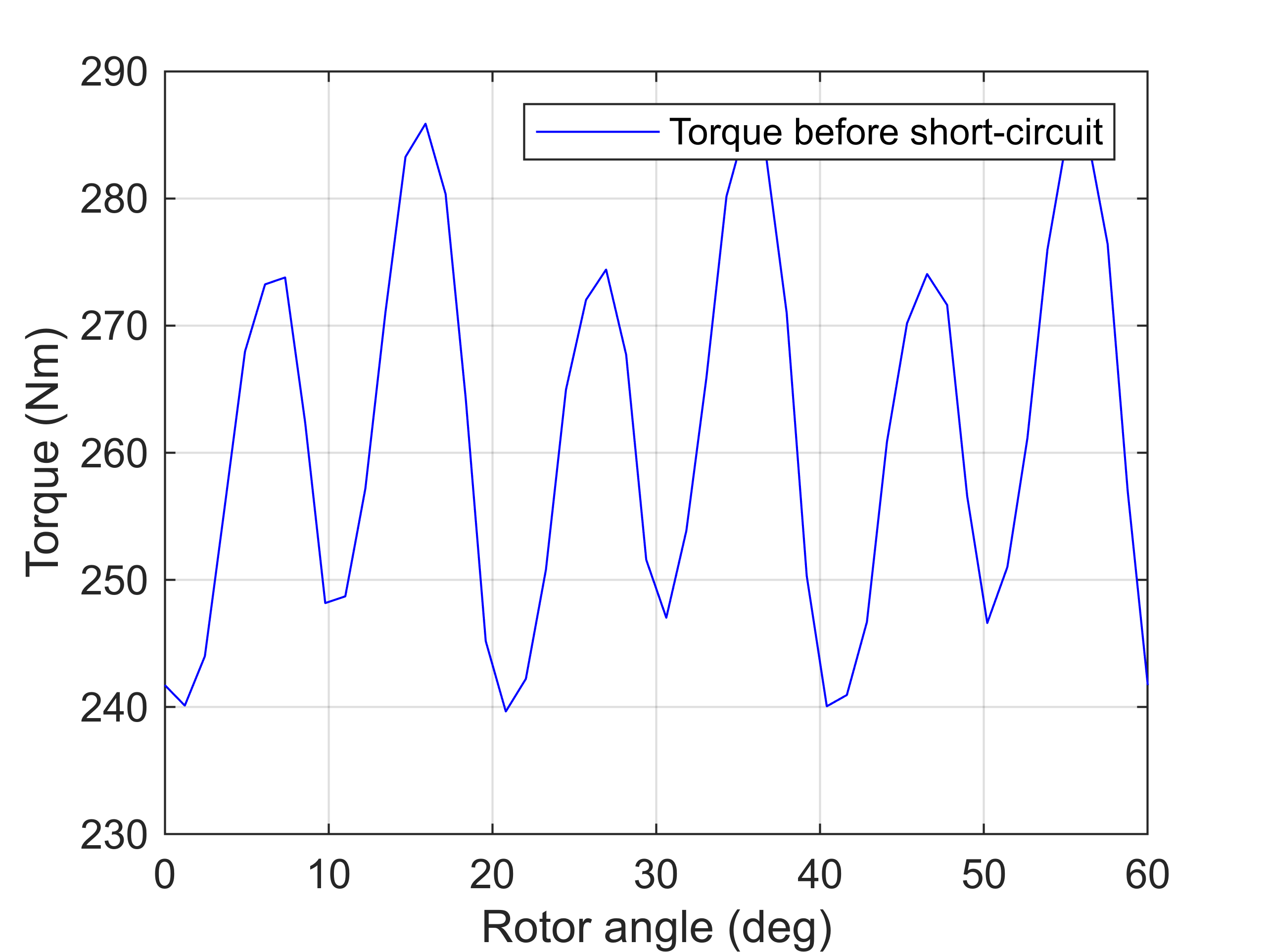

Healthy behaviour

Next, we simulate the behaviour before the short-circuit, computing the torque waveform at a rather large current density, using magnetostatic analysis.

rpm = 5000;

Jrms = 25e6;

%interesting circuits

phase_circuit = stator.winding;

spec = stator.winding_spec;

%initializing problem

problem = MagneticsProblem(motor);

%setting supply

Ipeak = sqrt(2)*Jrms * phase_circuit.conductor_area_per_turn_and_coil();

idq = [0; Ipeak];

angles = linspace(0, 2*pi/2, 50);

Ipeak = sqrt(2)*Jrms * phase_circuit.conductor_area_per_turn_and_coil();

Is_static = spec.xy(idq, angles);

phase_circuit.set_source('uniform coil current', Is_static);

%setting parameters and simulating

pars_static = SimulationParameters('f', rpm/60*dim.p, 'rotorAngle', angles/dim.p, ...

'silent', true);

stepping_solution = problem.solve_static(pars_static);

%computing and plotting the torque

T_before_short = motor.compute_torque(stepping_solution);

figure(6); clf; hold on; box on; grid on;

plot(angles/pi*180/dim.p, T_before_short, 'b');

ylabel('Torque (Nm)')

xlabel('Rotor angle (deg)')

legend('Torque before short-circuit')

Short-Circuit Simulation

Next, we run the short-circuit simulation in the same way as before.

%for improved simulation speed

for c = rotor.circuits

c.enabled = false;

end

%setting parameters

pars = SimulationParameters('f', rpm/60*dim.p, 'N_periods', 1, ...

'N_stepsPerPeriod', 50, 'silent', true);

%current supply, before short

Is = spec.xy(idq, 2*pi*pars.f*pars.ts);

%setting a ShortCircuit source

T_period = 1/pars.f;

source = ShortCircuit;

source.short_at = T_period * 0.2; %instant of the short

%supply-type before the short

source.supply_before_short = "terminal current";

source.supply = Is;

phase_circuit.set_source('circuit', source);

%solution

harmonic_solution = problem.solve_quasistatic(pars);

stepping_solution = problem.solve_stepping(pars);

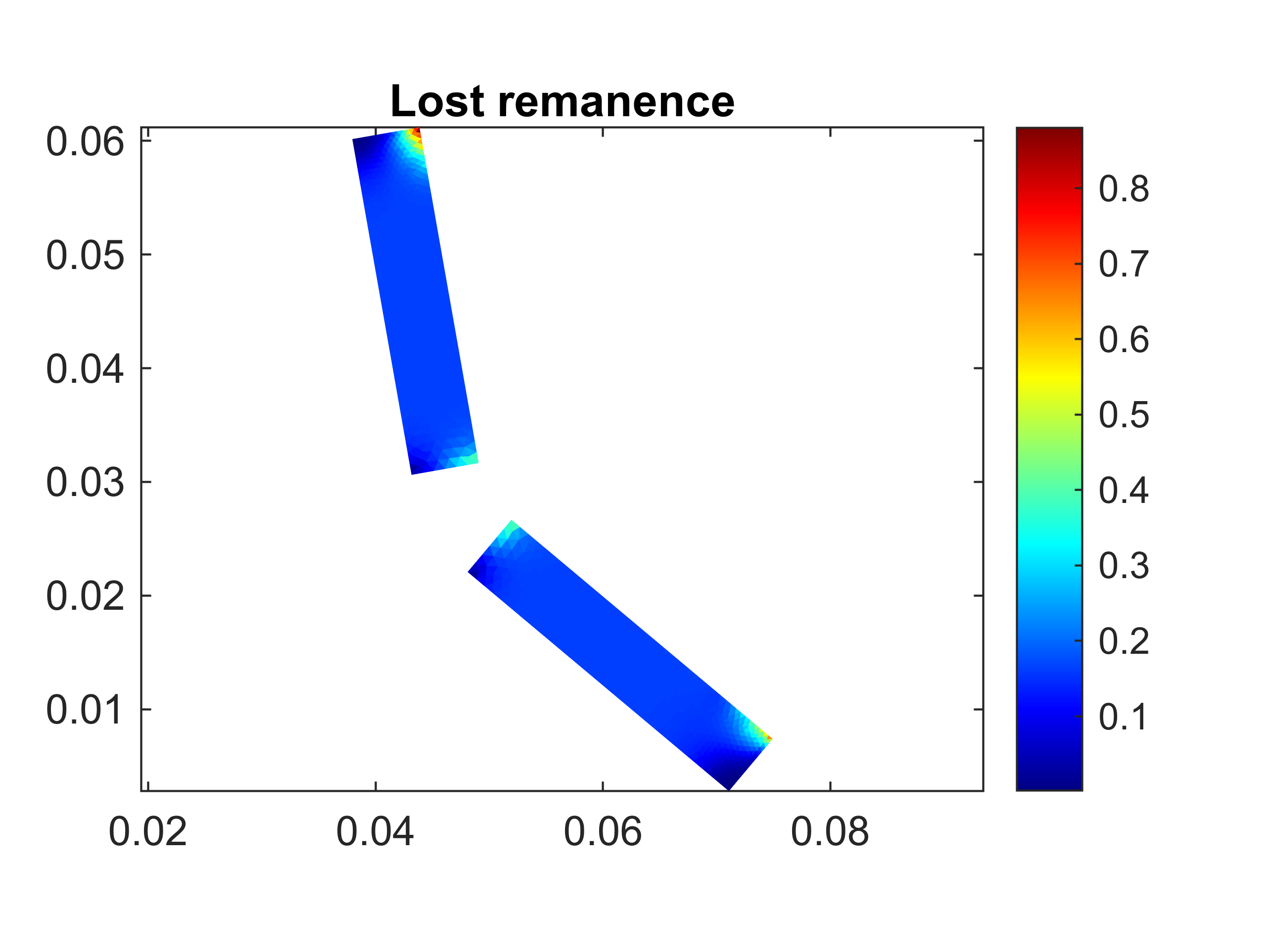

Post-processing

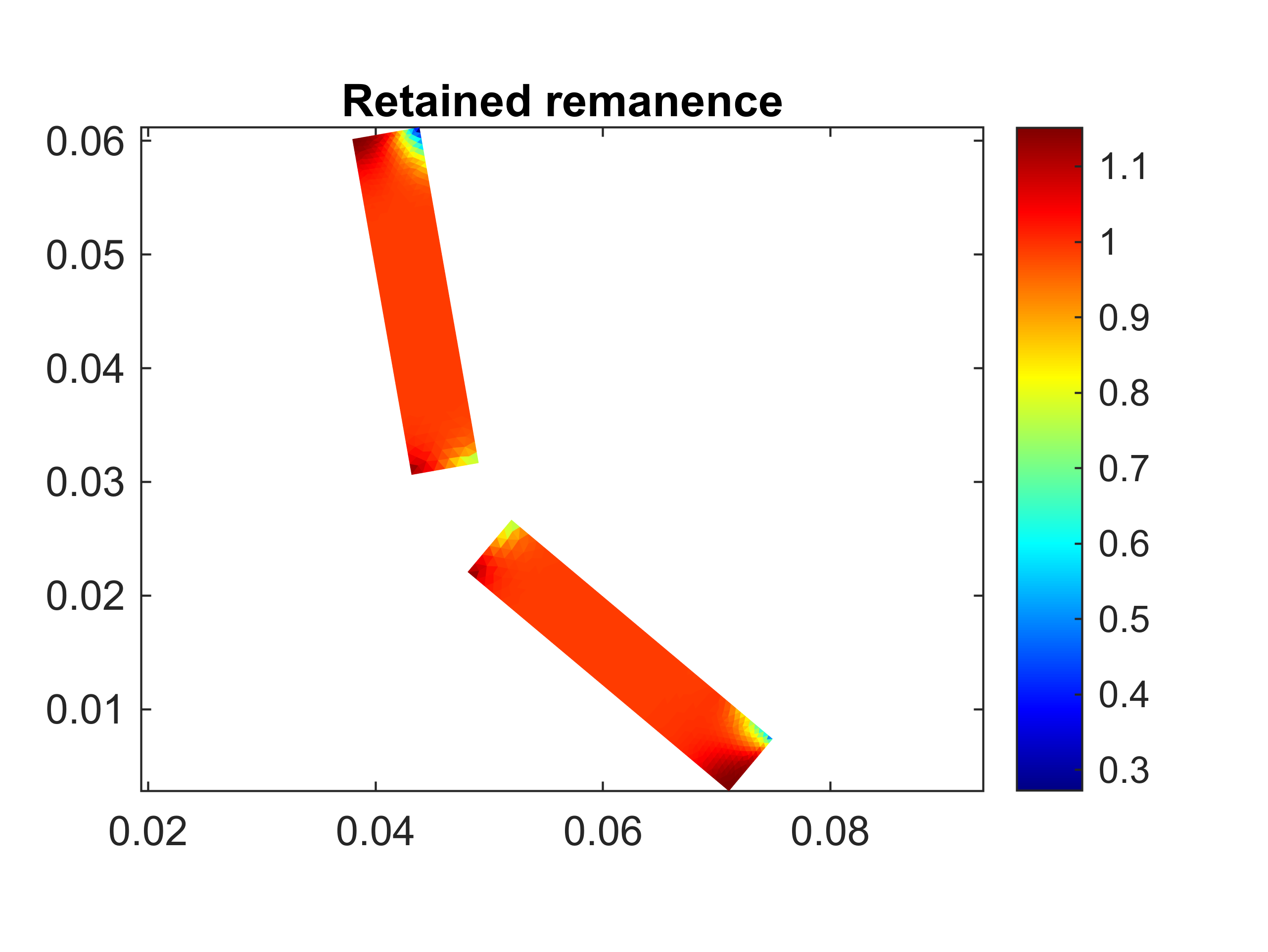

Next, we visualize the damage to the magnets. We plot both the actual remanence retained (i.e. the intersection of the B(H) curve with the H=0 axis), and the difference between the retained remanence and the remanence of a healthy magnet.

figure(4); clf; hold on; box on; axis equal;

title('Lost remanence')

demag_material.visualize_lost_remanence();

colorbar;

figure(5); clf; hold on; box on; axis equal;

title('Retained remanence')

demag_material.visualize_retained_remanence();

colorbar;

Performance after short-circuit

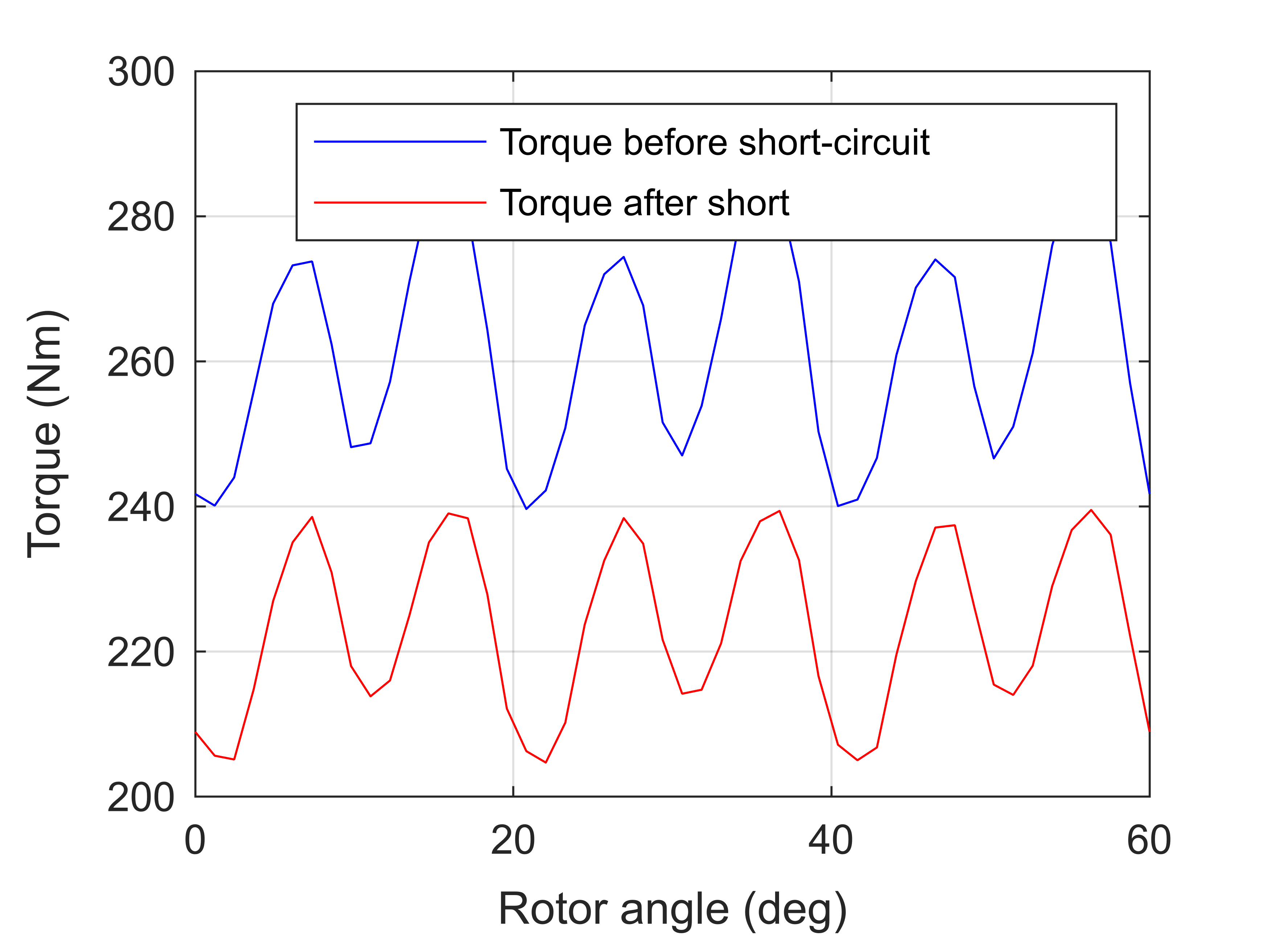

Finally, we recompute the torque waveform. Since we set the .retain_remanence property to true, the magnet material is now aware of its damaged state, and we see a rather significant loss in torque.

phase_circuit.set_source('uniform coil current', Is_static);

stepping_solution = problem.solve_static(pars_static);

T_after_short = motor.compute_torque(stepping_solution);

figure(6); clf; hold on; box on; grid on;

plot(angles/pi*180/dim.p, T_before_short, 'b');

plot(angles/pi*180/dim.p, T_after_short, 'r');

ylabel('Torque (Nm)')

xlabel('Rotor angle (deg)')

legend('Torque before short-circuit', 'Torque after short')